Understanding the Role of Automotive Camshaft Manufacturers in Diesel Engine Performance

The automotive industry is a complex and ever-evolving landscape where precision engineering meets innovation. Among the vital components that play a significant role in engine performance, the camshaft stands out. In this article, we will delve deep into the world of automotive camshaft manufacturers, their impact on diesel engines, and why their products are essential for both OEMs and aftermarket suppliers.

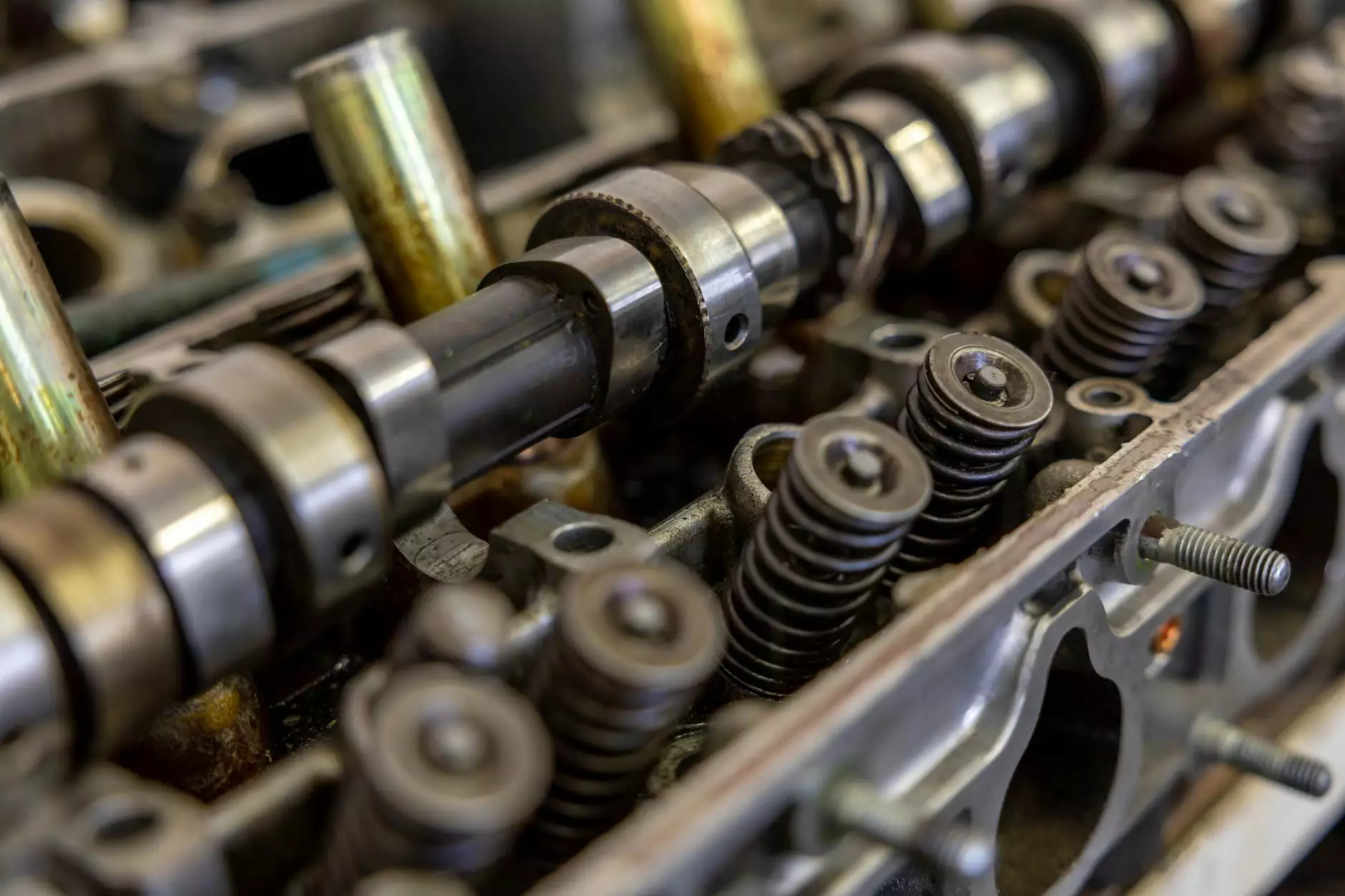

The Importance of Camshafts in Diesel Engines

The camshaft is a critical component of any internal combustion engine, but it takes on a unique significance in diesel engines. It is responsible for regulating the timing and movement of the engine’s intake and exhaust valves. This regulation is vital for optimizing power output, fuel efficiency, and emissions control.

How Camshafts Work

Camshafts operate by converting the rotational motion of the engine into linear motion that opens and closes the valves at the right time. The design and materials used in camshaft construction highly influence the engine's performance. Variations in camshaft profiles can lead to distinct engine characteristics—ranging from smooth and quiet operation to aggressive and powerful acceleration.

Types of Camshafts

- SOHC (Single Overhead Camshaft): This configuration uses one camshaft per cylinder bank, which can be efficient but may not allow for optimal performance in more complex engines.

- DOHC (Double Overhead Camshaft): This design features two camshafts per cylinder bank, allowing for better timing of valve operations, improved performance, and more powerful engines.

- VVT (Variable Valve Timing): Advanced camshaft systems enable engines to adjust valve timings dynamically, leading to enhanced performance under varying conditions.

The Role of Automotive Camshaft Manufacturers

Automotive camshaft manufacturers are crucial players in the automotive supply chain. They design, engineer, and produce camshafts using advanced materials and technologies to meet the demands of modern diesel engines.

Key Characteristics of High-Quality Camshafts

When sourcing camshafts, particularly for heavy-duty applications like diesel engines, several characteristics are essential:

- Material Quality: High tensile strength materials such as forged steel or high-grade aluminum are preferred for durability and performance.

- Precision Engineering: The accuracy of the camshaft profile directly affects the engine's performance. Innovative manufacturing technologies such as CNC machining are employed to achieve this precision.

- Surface Finishing: Advanced surface treatments like nitriding enhance wear resistance and extend the life of the camshaft.

- Weight Optimization: Lighter camshafts reduce the overall engine weight, improving efficiency without sacrificing strength.

Choosing the Right Manufacturer

Selecting the right supplier for camshifts is crucial for any business involved in the automotive industry. Here are some factors to consider:

- Industry Reputation: Look for manufacturers with a proven track record in the automotive sector.

- Technology Adoption: Suppliers that invest in the latest technologies typically produce higher quality parts.

- Customer Support: A responsive and knowledgeable support team can significantly enhance the working relationship.

- Customization Capabilities: The ability to tailor camshafts to specific engine requirements is a valuable asset.

The Future of Camshaft Manufacturing

As we look ahead, the landscape of automotive camshaft manufacturing is poised for change. With the rise of electric vehicles and stringent emission regulations, manufacturers are adapting to new challenges while also exploring advanced materials and technologies.

Innovations in Camshaft Design

Recent advancements in design and technology are revolutionizing the camshaft industry:

- 3D Printing: This technology allows for rapid prototyping and innovative designs that were previously impossible.

- Smart Camshafts: Integrating sensors and electronic controls can provide real-time data on engine performance, allowing for significant adjustments that improve efficiency.

- Sustainable Manufacturing Practices: Increased focus on sustainable practices includes using recycled materials and minimizing waste in production.

Conclusion

The role of automotive camshaft manufacturers in the automotive industry, particularly in relation to diesel engines, cannot be overstated. They are instrumental in ensuring that engines perform optimally while adhering to emission standards and efficiency requirements. As the automotive landscape continues to evolve with technology and sustainability in mind, these manufacturers will also adapt, paving the way for more innovative and efficient automotive solutions.

For businesses involved in the industry, such as client-diesel.com, understanding and collaborating with reliable camshaft manufacturers is crucial. By prioritizing quality, innovation, and performance, you can ensure that your engine parts meet the high standards of today's demanding automotive market.